Home » Navigating Market Uncertainty: Novarc’s Journey in Canada

Navigating Market Uncertainty: Novarc’s Journey in Canada

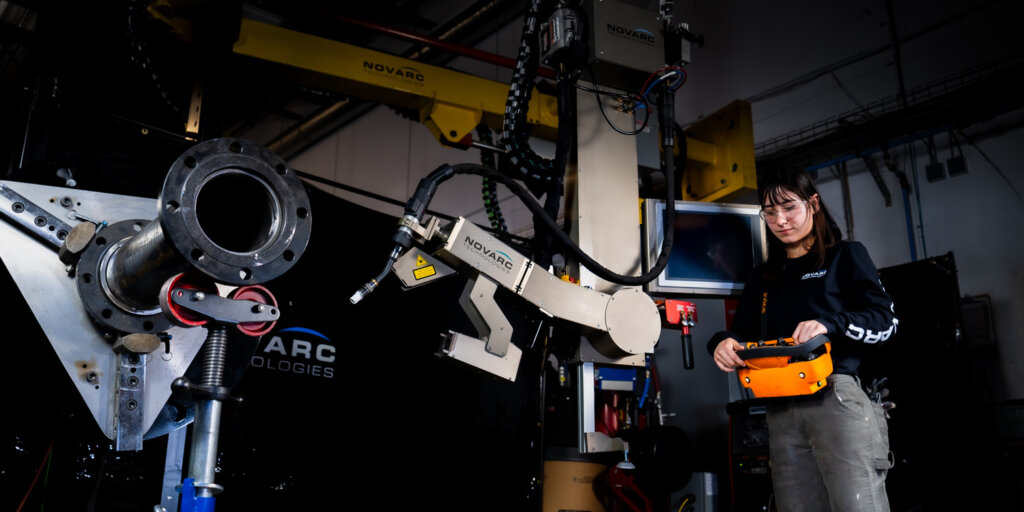

Novarc Technologies, a Vancouver-based company, exemplifies innovation in the field of welding through strategic partnerships and problem-solving. Founded in 2013 by Reza Abdollahi and Soroush Karimzadeh, the company emerged from a specific client request seeking safer methods for pipe welding in heavy industry. Their collaboration resulted in the creation of the first collaborative robot, or cobot, which redefined traditional approaches to industrial welding.

Industrial robots had been present since the 1960s, yet they lacked significant improvements. Over the past dozen years, Novarc's team has continuously advanced the technology, recently integrating computer vision to develop an artificial intelligence-enhanced system that boosts robot autonomy. This innovation, along with a practical and agile business approach, has fostered remarkable growth for Novarc.

The company recently completed a $71.6 million Series B funding round led by Export Development Canada, aimed at speeding up the commercialization of its technologies. Additionally, a strategic partnership with Miller Electric, a U.S. firm specializing in arc welding equipment, allows Novarc to enhance their products through collaboration, additionally opening up valuable U.S. market opportunities.

Karimzadeh emphasizes the increasing demand for welders, which exceeds supply due to both a generational shift in career interests and the decline of skilled workers in the industry. Novarc’s technology, specifically their NovEye system, can address this shortage by enabling human welders to direct AI-powered cobots—a solution that not only raises productivity but also simplifies the demanding elements of welding work.

While the impact of tariffs on materials like steel and aluminum remains to be seen, Karimzadeh is monitoring the situation closely. He acknowledges that customers currently hold inventory, which may delay market price adjustments, but anticipates eventual price increases due to various economic pressures.

The partnership with Miller Electric allows Novarc to leverage existing market channels in the U.S. for their new AI-focused product line while maintaining a robust presence with their comprehensive robotic solutions. This dual-market strategy provides an effective response to the uncertainties posed by global trade dynamics.

Since expanding geographically in 2019, Novarc has steadily intensified efforts in Australia, Southeast Asia, and Europe to diversify revenue streams. Despite the U.S. market's attractiveness, the importance of having multiple markets is recognized as essential to long-term sustainability.

Looking ahead, Karimzadeh expresses optimism about the tech sector's future and insists that productivity gains through technology will directly improve living standards. The ongoing shortage of welders, paired with increasing global demand for automation solutions, positions Novarc favorably. Past disruptions, such as those experienced during the COVID-19 pandemic, have built resilience in the company, allowing them to adapt rapidly to new challenges.

The company continues to explore potential applications for its technology, focusing on economically viable solutions rather than mere possibilities. While requests for automating complex tasks like underwater or overhead welding exist, Novarc prioritizes areas where they can deliver tangible value.

Karimzadeh also suggests that embracing such advanced technologies might attract younger individuals to welding careers, transitioning the field from one traditionally seen as dull and hazardous to one that is cleaner, more innovative, and approachable. By shifting the focus from manual labor to machine operation and supervision, Novarc aims to make welding an appealing career choice for future generations.

MaRS Discovery District

https://www.marsdd.com/

MaRS is the world's largest urban innovation hub in Toronto that supports startups in the health, cleantech, fintech, and enterprise sectors. When MaRS opened in 2005 this concept of urban innovation was an untested theory. Today, it’s reshaping cities around the world. MaRS has been at the forefront of a wave of change that extends from Melbourne to Amsterdam and runs through San Francisco, London, Medellín, Los Angeles, Paris and New York. These global cities are now striving to create what we have in Toronto: a dense innovation district that co-locates universities, startups, corporates and investors. In this increasingly competitive landscape, scale matters more than ever – the best talent is attracted to the brightest innovation hotspots.