Home » Beyond farm to fork – MaRS Discovery District

Beyond farm to fork – MaRS Discovery District

Our eating habits need an overhaul.

Growing and processing food is a massive source of greenhouse gases: Agriculture alone accounts for nearly half of all methane emissions, two-thirds of nitrous oxide emissions and 3 percent of carbon dioxide emissions each year.

Climate change is also making it harder to produce food. Extreme weather events are becoming far more common, and all those floods, droughts, wildfires and severe storms result in lower crop yields and higher food prices. With the world’s population on track to hit 10 billion by 2050, we need new ways of putting food on the table without trashing the planet.

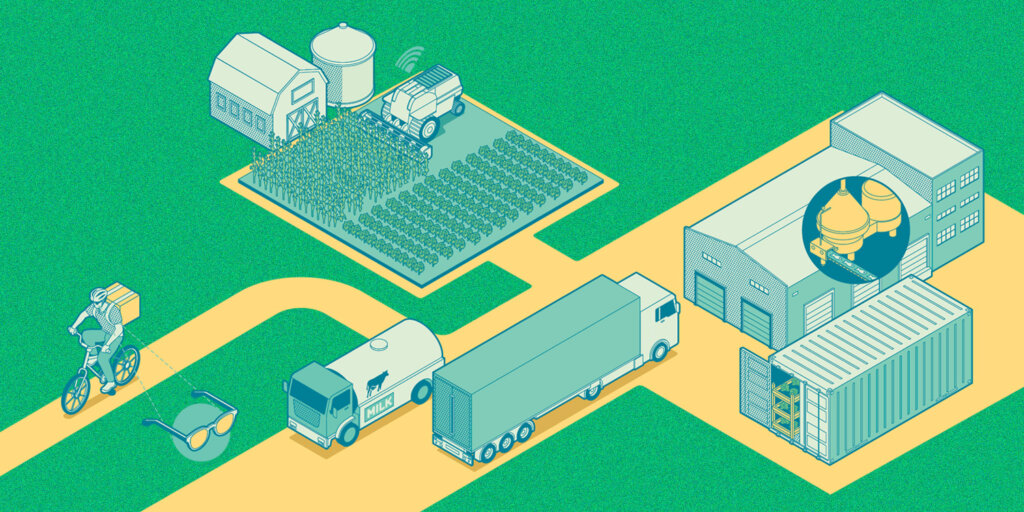

It’s a big challenge — novel solutions are needed throughout the food chain, from farm to table to green bin. Canadian researchers and entrepreneurs are tackling the problem from all angles: cooking up animal-free protein, growing crops in shipping containers and transforming our leftovers.

A tiny solution with a big impact

In farming, timing is everything. Vive Crop Protection has developed fungicides and pesticides using a nanoscale system that delivers exactly what crops need, exactly when and where they need it. This cutting-edge technology can be mixed with liquid fertilizer and helps growers improve yields while using less water. The Mississauga company has been selling its products in the United States for the last seven years. This spring, Health Canada gave the green light to one of its fungicides, which will be sold here to help potato farmers combat soil-borne diseases.

Growing more with less

Researchers at the Ottawa Smart Farm are harvesting bumper crops of corn with less water, less fertilizer and even fewer seeds. By using autonomous tractors outfitted with sensors as well as 5G technology and analytical platforms, they can precisely target the areas of the field that require additional moisture and nutrients. That extra TLC reduces the resources needed while also producing up to 30 per cent larger yields (plus cobs that are bigger and juicier). The pilot project is in its final year of gathering data. Sonya Shorey, vice president of strategy and marketing at Invest Ottawa, the development agency that launched the farm in 2020 in partnership with the City of Ottawa, says the results show “very significant wins” in reducing greenhouse gas emissions.

Smart delivery

To cut down on the spoilage and waste that happens before food even reaches the grocery store, Bluicity affixes tracking devices to pallets, bins and boxes. These sensors monitor conditions, and the collected data helps optimize the supply chain.

Home-grown produce

Salad is always a nice light option, but if the arugula is trucked in from California, those greens can leave a hefty carbon footprint. (In fact, a recent study found that transporting what we eat makes up nearly one-fifth of carbon emissions in the food system.) Instead of shipping produce across the continent, Ottawa startup Growcer manufactures hydroponic farms in custom-built containers to help communities grow local produce anywhere, year-round. Each modular “farm” features around 2,500 planting slots and can grow more than 140 varieties of produce.

A clean plate

About one-third of all household waste is made up of takeout boxes, plastic wrapping and other food packaging. Kayli Dale and Jacquie Hutchings started Friendlier in 2019 to change that. The Guelph-based company now provides more than 200 restaurants, cafeterias and grocery stores with returnable containers that are tracked by QR codes. “Our goal is to make it as easy for businesses and consumers to use reusable packaging as it is for them to use single-use packaging right now,” Dale says.

Milking the science

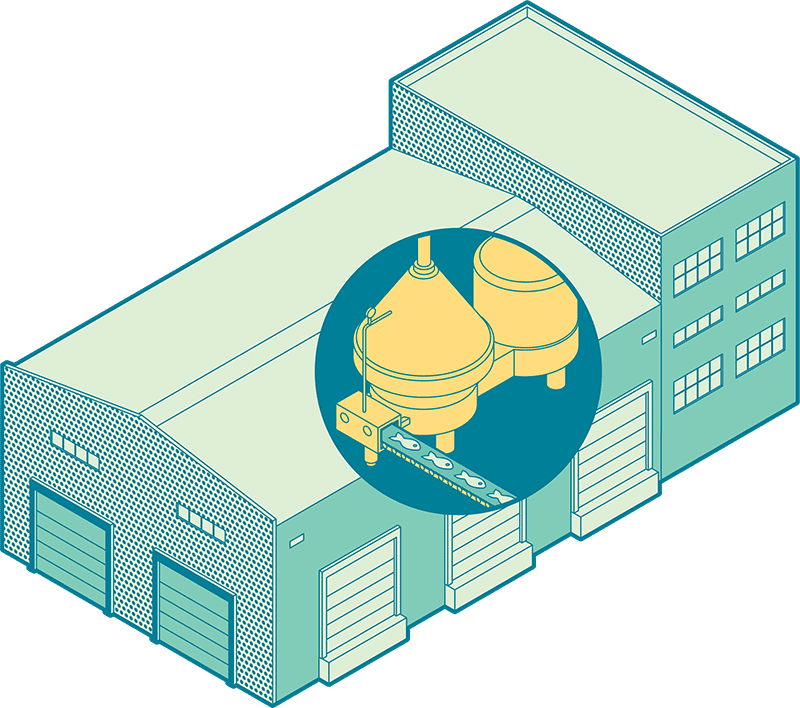

Early-stage foodtech company Opalia is scaling up the production of milk — with no Holstein cows in sight. The company produces its dairy in a bioreactor using genetically engineered bovine mammary cells. Identical to cow-sourced whole milk in taste and composition, Opalia’s beverage could help reduce the extensive environmental impact of traditional dairy farming.

A different kind of seafood

Rather than use a hook, line and sinker, Halifax-based Smallfood employs shiny 100-litre bioreactors. Marc St-Onge and his team ferment microalgae to create a protein powder with the same amino acids, omega-3 content and flavour as wild-caught fish. So far, they’ve made crab cakes, fish cakes and sashimi, and are working to expand into producing feed for poultry farming and aquaculture. The company is collaborating with food startup Terra Bio and chef Doug McNish to create a fish fillet alternative. And in May, Smalfood was named one of six finalists in the global US$15-million XPRIZE Feed the Next Billion challenge. “We’re on a mission to help preserve our oceans,” says St-Onge.

Transforming scraps

Close to 60 per cent of the food in Canada is lost or wasted each year. That’s a lot of land, labour and energy dedicated to delicacies that never get consumed. Genecis is transforming food waste into biodegradable plastic. The company plans to launch a collection of consumer products — their aim is to make everything from kitchenware to clothing to sunglasses.

Illustrations: Remie Geoffroi

MaRS Discovery District

https://www.marsdd.com/

MaRS is the world's largest urban innovation hub in Toronto that supports startups in the health, cleantech, fintech, and enterprise sectors. When MaRS opened in 2005 this concept of urban innovation was an untested theory. Today, it’s reshaping cities around the world. MaRS has been at the forefront of a wave of change that extends from Melbourne to Amsterdam and runs through San Francisco, London, Medellín, Los Angeles, Paris and New York. These global cities are now striving to create what we have in Toronto: a dense innovation district that co-locates universities, startups, corporates and investors. In this increasingly competitive landscape, scale matters more than ever – the best talent is attracted to the brightest innovation hotspots.