Home » KA Imaging partners with Grand River Hospital on X-ray detector innovationInnovation Factory

KA Imaging partners with Grand River Hospital on X-ray detector innovationInnovation Factory

A Waterloo company is working with Grand River Hospital (GRH) to improve patient outcomes with a portable X-ray detector that provides health-care workers with high-quality images right at the bedside.

KA Imaging and GRH are collaborating on a commercialization project in the hospital’s intensive care unit (ICU).

The project is supported by the Coordinated Accessible National Health Network (CAN Health), a federally funded initiative that’s working with Communitech to get more Canadian innovation into the health-care system. The goal is to improve patient outcomes, increase efficiencies and support Canadian companies.

“Partnering with CAN Health allows us to be able to allocate resources internally to focus on innovation projects (and) not take resources away from the care of the patient,” says Carla Girolametto, Director of Innovation and Research at GRH.

CAN Health is based on an “integrated markets” model – a collaborative network of hospitals, clinics and health-care organizations that are interested in using innovation to solve common challenges.

One of those challenges is finding the time and funding to try out innovative new products and services. Members of the network, known as Edges, can apply to CAN Health for the support needed to pilot a specific innovation. The results of the project are then shared with the network, providing data-based validation that helps other Edges evaluate how the product might help them.

GRH, which has a long history of assisting with medical research and clinical trials, was one of the first hospitals to join the network. So far, it has participated in three CAN Health-supported projects.

“It’s really what is going to help innovation take off in many hospitals, not just Grand River,” says Girolametto, who has worked in research and clinical trials at GRH for nearly 20 years.

For companies like KA Imaging, the benefits are many. The projects generate data that help them market their products, it provides a network of potential customers and it helps them improve their technology by testing it in real working environments.

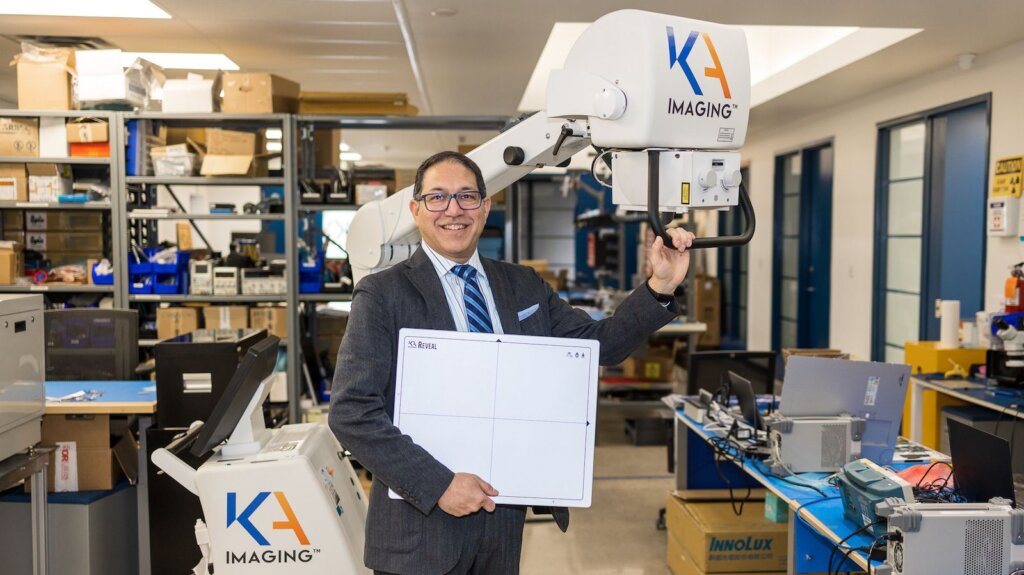

“We already have the regulatory approvals,” says Amol Karnick, co-founder and CEO of KA Imaging. “The CAN Health project is going to help us accelerate our sales capabilities by providing meaningful and useful patient data that we can share with other hospitals.”

The feedback from GRH staff has also helped KA Imaging adjust its technology to better integrate with workflow processes.

“They’ve helped us create a better product,” says Karnick.

Launched in 2015, KA Imaging evolved out of research conducted in the lab of co-founder and CTO Karim S. Karim, a professor of electrical and computer engineering at the University of Waterloo.

Karim and his students in the Silicon Thin-film Applied Research (STAR) group became interested in developing a low-cost X-ray detector that could be used in developing countries to screen for tuberculosis.

Karim approached Karnick about starting a company. The two had met previously when Karnick served as an executive in residence at Communitech.

“He reached out and asked if I’d be interested in putting this company together,” recalls Karnick. “Initially, our target was more a social entrepreneurship to create low-cost X-ray for TB diagnostics and other diagnostics in the developing world.”

They also invited Sina Ghanbarzadeh, an alumnus of Karim’s STAR group, to join as co-founder and lead design engineer. (Ghanbarzadeh made significant contributions to the company’s technology. He died of cancer in 2021 at the age of 32.)

KA Imaging makes X-ray detectors – the component in the X-ray process that receives the radiation after it passes through the patient, and then converts it into images.

Karnick says the company’s technology is an advancement on dual-energy detection. Both are designed to overcome a shortcoming in traditional X-ray images where the anatomical overlapping of bone and soft tissue can result in unclear images.

KA Imaging’s portable Reveal 35C detector yields three images with a single dose of radiation: a traditional X-ray image, a separate image highlighting just the bones and another separate image highlighting the soft tissue. It also eliminates what’s known as “motion artifacts” – blurring caused by patient movement during the X-ray process.

The Reveal 35C gives medical staff a much clearer picture of things like lung nodules, pneumonia and bone fractures. It also helps doctors and nurses see whether catheters, lines and tubes are inserted correctly inside a patient.

Computed tomography (CT) scanners provide images with greater clarity, but these are generally large, stationary systems that require the patient to be transported to the machine.

One of the advantages of the KA Imaging detector is that it can be deployed at the bedside. That saves time and resources, and gives medical professionals more certainty about what they’re seeing in the image.

“We’re trying to make it easier and faster, and provide higher confidence in the diagnoses, which is much better for patient outcomes and health care in general,” says Karnick.

KA Imaging has worked with Grand River Hospital in the past, collaborating on clinical trials of the portable X-ray detector in its oncology unit.

GRH’s Carla Girolametto says dual-energy X-ray technology has been around for some time, but older versions had limitations such as the need for dedicated rooms, more radiation than traditional X-ray and image-quality issues.

KA Imaging’s detector solves these problems and can be fitted for use with existing X-ray equipment, including portable machines.

“This means that hospitals can upgrade existing X-ray units to create images that are close to CT image quality without significantly increasing the radiation dose – compared to traditional X-ray – while using the units they already have,” says Girolametto.

In the ICU project, the Reveal 35C detector – a flat rectangle about the size of a computer monitor – is attached to the hospital’s portable X-ray machines and used to help clinicians check tube and line placements and monitor patients to prevent respiratory problems.

The KA Imaging detector has regulatory approval from Health Canada, the U.S. Food and Drug Administration and similar regulators in other countries and regions.

The Reveal 35C is being used in other Canadian hospitals, including Toronto General and the Sunnybrook Research Institute, with the help of other innovation programs.

The company has also been selling the detector abroad. In Taiwan, the Reveal 35C is being used in a portable X-ray system on a bus that travels through neighbourhoods providing early detection scanning for things like lung disease.

“They hold a clinic and the bus goes around and they have 250 to 300 patients every sat,” says Karnick. “They’ve imaged 8,000 patients already in about three months.”

In addition to the Reveal 35C, KA Imaging makes X-ray detectors for veterinary uses, industrial purposes (such as pipe inspection) and for security (baggage inspection).

The company has received interest and funding from In-Q-Tel, an innovation investment vehicle for U.S. intelligence services.

“They looked at our detector and they like what we can do with separation for identifying certain materials,” says Karnick.

While the COVID-19 pandemic affected the company’s business plans, KA Imaging spent much of last year developing its marketing and sales resources.

The company, which employs 40 people, used Communitech’s Outposts employer-of-record service to hire six salespeople in the U.S. It also brought on a new distributor in the U.S., and it has other distributors in places like Australia, Taiwan, Malaysia and Pakistan.

“I love Outposts,” says Karnick. “It makes our job a lot easier.”

KA Imaging has raised funds through research grants and investment capital, and is considering a Series B round.

The company sold five detectors in January and has generated about $3 million in revenue over the past three years, says Karnick.

“It’s a great start for 2023,” he says. “And it’s going to ramp up.”

Did you know? KA Imaging is working with Innovation Factory and the Federal Development Agency of Southern Ontario to leverage the SOPHIE program towards the research, development and commercialization of their X-ray technology.

Innovation Factory

Innovation Factory is a business accelerator, dedicated to helping Ontario-based businesses launch, scale, and succeed. Supporting the Brant, Halton, Hamilton and Norfolk regions, we provide start-ups, and scaling companies with advisory services, training, mentorship, and strategic connections to help bring disruptive technologies to market, leverage intellectual property, increase revenues, attract investment and create jobs. Innovation can happen anywhere, our goal is to make it work everywhere. We work to elevate key industry sectors including advanced manufacturing, clean tech, information technology, smart transportation, life sciences & health care and social innovations. We are passionate about driving the growth of Ontario businesses like yours. Whether you are an entrepreneur bringing new ideas to market or a scaling business trying to get to the next level, we want to help.